ABOUT US

The company is a dynamic international investment, trading, engineering, procurement, construction, installation, and commissioning (EPCIC) and life of field services (LOFS) contractor. We have extensive international experience in the offshore environment. We can provide sustainable turn-key solutions to a large range of offshore developments, including pipelines, cable installation, single-point moorings (SPM), offshore structures, and subsea infrastructure construction services. Our pipelay capabilities include small and large-diameter rigid pipelines, flexible pipelines, some of the most complex subsea pipeline installations, and shore crossings in India, South East Asia, the Middle East, and Africa. We operate internationally from offices in Europe and the United Arab Emirates. Our experienced, proven project managers and management systems focus on safety and quality, driving the best outcome for our clients across the project delivery life cycle.

EPCIC SERVICES

PE can take on the most challenging projects across the offshore oil and gas project lifecycle. Our multi-disciplinary expertise and background ensure our clients have access to a “one-stop shop” for full services delivery, covering project management, engineering, procurement, fabrication and construction, transportation and installation, and commissioning both onshore and offshore. We provide services for Greenfield and Brownfield projects, with innovative and cost-effective engineering solutions to the most technically challenging projects.

EPCIC

expertise and capabilities include:

SUBSEA PIPELINES (RIGID AND FLEXIBLE AND SURF INSTALLATION)

PE offers its clients a capability that includes large and small-diameter subsea pipelines. PE has experience with nearshore, shallow water (150mtr) and infield pipelines, SURF (subsea, umbilical, riser, and flowline) installation, shore crossings, and tie-in spools. We own a fleet of equipment optimally suited to work, and we pursue and have experience in a wide range of environmental and geographic conditions. We offer rigid pipe-lay installation capability using traditional S-lay and surface and bottom tow methodologies. Our capabilities include flexible pipelines, and our equipment provides reel drive systems to support such work. We also have extensive experience in shore crossings and shore pull installation. PE offers a complete installation service, including aspects such as trenching and backfill and associated onshore works.

MARINE LOADING AND TERMINAL FACILITIES

Construction of marine facilities

PE has extensive experience in the construction of marine facilities to support the oil and gas industry. Facilities include jetties and berths for the receipt and export of products such as crude oil LNG, LPG, aviation fuel, diesel, and fuel oil.

Marine structure

Our capabilities include the marine structure, topside piping, mechanical, electrical, instrumentation, control systems, safety and fire systems, navigation systems, cargo equipment works, onshore storage, and terminal facilities.

Floating & Offloading

PE has extensive experience in the design and supply ofintegrated process topsides for FPSOs and other floating production platforms. Our capability includes process optimization studies, conceptual and detailed design and PMC consultancy through to full EPCIC project delivery.

LIFE OF FIELD SERVICES

PE has the capability to deliver the Life of Field Services (LOFS) solution for both Brownfield and Greenfield offshore projects. Internationally, the PE has continuously delivered some of the world’s most ambitious and logistically challenging operations and maintenance contracts across the construction, services, infrastructure, and extractive industry sectors.

OUR LOFS CAPABILITIES INCLUDE:

. Operations and maintenance

. Inspection, repairs and maintenance

. Emergency pipeline repair services.

Our primary goal is to maximize facility utilization and minimize risk through both passive and activerisk mitigation measures employing sophisticated Risk Management (ARM) and Asset Management Software (CMMS), active communications and

interface management with facility stakeholders, proactive safety and security plans.

We offer a range of subsea construction services, including diving and ROV services with state-of- the-art equipment delivered through our in-house diving operations team. Our operations management structure, vessel spread and execution methodology offers our clients

innovative, cost-effective solutions for their LOFS requirements.

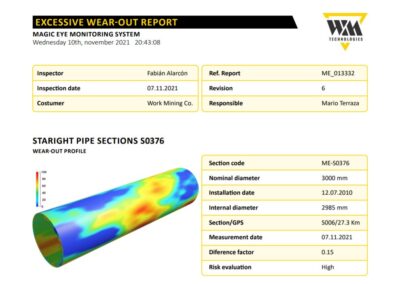

Magic Eye 3.0

Own creation, the only high-quality 3D laser scanner, with remote data transfer for long-term piping monitoring without stopping the plant, obtaining more than 1,300,000 data per second with its technological integration of multiple sensors, artificial intelligence and machine learning, allow to maintain and control, with a non-invasive system, the structural integrity of the pipings. Allows monitoring of all types of fluids, all types of gases, acid and blending. Patented Product.

SERVICES:

Monitoring of Internal Conditions of Ducts

PE offer monitoring service of internal surfaces of ducts for all types of fluids, acids and gases with our MAGIC EYE 3.0 LASER SCANNER of our own and patented creation, using T.O.F sensors and more than 1,300,000 measurements per Second, this data is stored and arranged in a cloud for consultation and subsequent treatment, enabling the use of data analytics techniques, allowing the structural integrity of the pipelines to be maintained, all without stopping the plant or processes.

TECHNICAL ATTRIBUTES

• No Wires Required

• Energy Autonomy

• Trade with Existing Flow

• Your Data Allows 2D or 3D Visualization

BENEFITS

• Only One Company Required – WM Technologies

• Knowledge about the Internal Condition of the Pipeline

• Adequate Allocation of Resources for Maintenance

• No Duct Emptying Required

• Operational Continuity

PERGASEURONORDIC CAPABILITIES

PIPELINES

- Design

- Procurement

- Repairs

- Specialist Leak

- Repairs

- Pipelay

- Commissioning

- Pipeline

- Abandonment &

- Recovery

ASSET REFURBISHMENT

- FPSO

- FSO

- SPM (Calm Buoy)

- Crude Process

- Equipment

- Gas Process

- Equipment

- Produced Water

- Equipment

- MOPU

SPECIALITIES

- Desalination Plants

- Water Purification Plants and Localized Systems

- Sewerage Treatment Facilities

- Water Delivery and Supply Infrastructure

- Commercial Irrigation Systems

OIL & GAS

- EPC, EPCM &PMC

- In-Stock Production Equipment

- Fast-Track Project Execution

- Modular Plug & Play Process Skids

- Gas Recovery Solutions

- Produced Water Treatment

- Subsea Operations & Maintenance

- Marginal Fields

MARINE & SUBSEA

- Vessel Management

- Vessel Chartering

- Port Agency Services

- Anchor Handling Tugs

- Security / Fast Crew Vessels

- Oil Spill Emergency

- Response Vessels

- Dive Support Vessels

- ROV Support Vessels

- Bunkering Operations

- Subsea Pipeline Installation (New& Remediation Works)

RENEWABLES

- Solar

- Wind

- Hydro / Tidal

- Waste

- Conversion

- Plastics To Power

- Plastics To Fuel

ENVIRONMENT

- Oil Spill

- Chemicals

- Laboratory Works

- Oil Spill Clean Up

- Environment

- Friendly

- Chemicals

Since

1988

KEY ENVIRONMENTAL OBJECTIVES

- ZERO LEVEL 1 ENVIRONMENTAL DAMAGE

- SYSTEMATIC REDUCTION OF LEVEL 2 AND 3 ENVIRONMENTAL DAMAGE

- COMPLIANCE WITH LEGAL, CONTRACTUAL AND REGULATORYOBLIGATIONS

- MAINTAIN CERTIFICATION OF THE HSE MANAGEMENT SYSTEM

Charles Ashwell, Managing Partner is a dynamic, self-motivated and innovative manager with over 38 years experience in the energy sector. An effective team-leader with excellent communication and interpersonal skills, with a proven track record of successfully managing projects from conception to operation, delivering results on time and within budget

- Involved in development of underwater welding techniques and emergency pipeline repair packages

- FPSO and FSO management

- Development of offshore LNG

- Established the first hyperbaric welding facility in the UK

- Multiple hyperbaric welding pipeline tie-ins and repairs in Australia, China, Iraq, Malaysia, New Zeeland, Norway, UK and Vietnam

- Development of isolation PIGs and clamps for pipeline repairs and abandonment

- Project Manager or Construction Manager for the following Subsea Pipelines:

- Statoil – Zeepipe Development Project, 1000 km of 40 inch pipelines (814 Km and 286Km)

- Statoil – Europipe Development Project, 620 km of 40 inch pipelines

- Shell – Malampaya 504 km of 24 inch pipelines (some areas of the pipeline were laid in 620 m water depth)

Clint Covey, Managing Partner

Marine Operations Specialist with a background in Marine and Subsea Operations, Clint has multi tier management capabilities and a track record of delivering results in major offshore EPC Projects and O&M contracts. Clint is motivated and innovative with 20 years of experience in management, from project inception, execution and delivery, adept in directing all aspects of marine and subsea operations

- Technical planning and preparation of all documents and procedures for diving campaigns and operations.

- Formed Global Process Systems in 2000, under which GPS group developed major fabrication shops in Singapore, Batam Indonesia, and Mafreq and Mussafar in Abu Dhabi

- Marine Engineering Diving Services- As Project manager, managed onsite dive team and all aspects of the project budget, technical planning in preparations for diving campaigns. Projects that were undertaken are gas line repairs South Pars Oil Field, SPM removal and installation in Iraq, Salvage operations RAK and Oman, and Crude Oil pipeline Repairs Iran

- Habtoor Leighton Group- Sub contractor vessel inspection and compliance vetting, planned and forecasted the marine and plant consumables,Loading of all fabricated structures/ piles ranging from 5MT-150MT and support materials, implementation of reporting and HSE procedures for all marine support vessels and Development and implementation of emergency evacuation procedures of all construction and support vessel

EPCIS & LOFS

Get in touch

- STOCKHOLM SWEDEN

- Phone: +46 8 800 600

- UNITED ARAB EMIRATE

- Phone: +971 4 556 4800

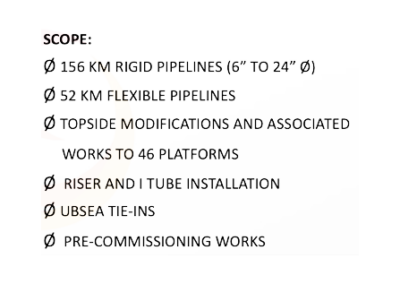

PERGASEURONORDIC TRACK REC

Murphy Oil, West Patricia Gas Platform 1,400 ton Sarawak, Malaysia

25,000 DWT high-pressure loading jetty Basra gas company, Iraq – Jetty

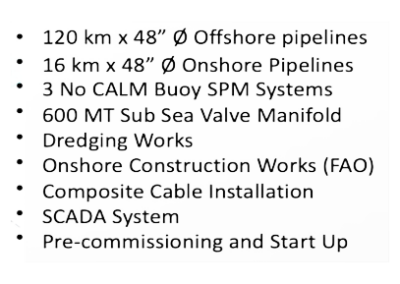

Iraq Export Expansion Reconstruction Project. Phase 3

Pipeline Replacement Project. Oil & Natural Gas Corp. Mumbai, India

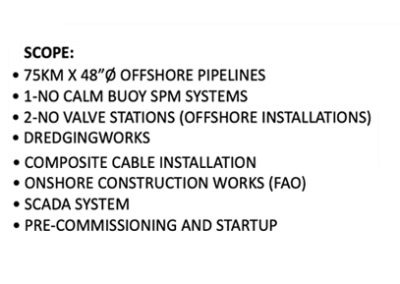

Offshore Pipelines – Shuqaiq 2 .Residual Offshore Construction.India